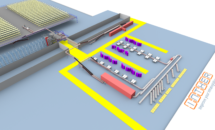

Inther Logistics Robotics introduces the Automated Document Inserter (ADI). This completely new automation product fully automatizes the insertion of A4 documents into cartons. A practice case at H. Essers in Belgium shows that the ADI increases both the efficiency as well as the quality of the packaging process.

The ADI not only prints and inserts documents, but also buffers and folds them. Depending on the average number of pages per document the capacity reaches up to 450 parcels per hour. As the right document is always in the right carton potential manual errors and costs are prevented. The ADI is a stand-alone system which takes the full process in own control (instead of the WCS/WMS). Inther’s experience with the Automated Document Applicator (ADA) has been used as technological basis. The ADA performs the same process but applies the documents to the outside of cartons instead of inserting them.

Several months ago, system integrator Inther implemented the first ADI in the warehouse of H.Essers in Courcelles, Belgium. An increase in the efficiency and quality of the packaging process is mentioned by logistics provider as the main reasons for the investment decision. The major technical advantage of the solution is that it folds the documents in such a way that it is possible to insert them also in smaller cartons. This functionality fully reflects the trend of ever-smaller cartons used for e-commerce applications. A fully automated double-checking system guarantees that the documents are always in the right carton.

Tags:

ADA, ADI, Automated Document Inserter, Inther, Inther Logistics, Inther Logistics Robotics, Packaging

Inther Logistics Engineering sold two Automated Documen...

In recent years, drastic measures have been carried out...

Inther Logistics Engineering and SRD Maschinenbau sold ...