The renewed RRE140-250H Reflex Series has a lot to offer according to Toyota Material Handling Europe: a brand-new mast with improved lifting performance, higher stability and lower energy consumption. Also, the steering has been improved and the reach truck has been equipped with a handy laser tool. We tested the truck firmly on our testing track.

A new truck does not necessarily have to have a completely new design. That is evident when we see the new Reflex for the first time. Initially the differences at and around the chassis barely are noticeable, however they are present: the handle is longer and covered with rubber, the step has been increased, other wheel caps have been mounted and the ventilation slits have a different design. The other, more important differences, are only to be noticed inside the truck. For example, the base plate is adjustable in height for an optimum seating position. Here the electrical control is an option, standard the new reach truck comes with manual adjustment.

Another improvement is the new seat fabric. As a result of getting off the truck, the left front corner side of the chair typically wears off faster than the rest of the chair. At this spot a different, much more durable material is being used.

The biggest optical and structural difference is found in the mast and the fork carriage. Toyota offers four different mast types, each with specific advantages for lifting height and capacity. By using leaner, but deeper profiles the stiffness has increased noticeably. The mast itself has been expanded and offers a better view thanks to another arrangement of the free lifting cylinder and the hoses. The fork carriage has also been renewed and includes a larger viewing window. By placing the cylinders of the remaining mast sections at the front of the mast, Toyota expands the support force to the place where it is most needed. All this results in masts with more residual capacity, less swing and torque, and a greater overlap ratio, making it possible to lift higher than before with a lower vehicle height. In addition, the new series deliver higher maximum height to 13 meters and more residual capacity. The bigger models of the truck are equipped with high speed lifting as a standard. These speeds are now also optionally available for the 140 and 160 models.

For all models, with the exception of the truck on solid tires, Toyota provides the option to place a Lithium-Ion battery with a capacity of 308 Ah (standard) or 448 Ah.

Our test truck is the Reflex RRE160H with a lifting height of 7 meters. The truck is equipped with almost every option, including the glass roof for extra clear view upwards, the laser tool for extra easy positioning of the fork, the electric floor adjustment, and the security light in both directions (available with blue or red light). The test truck is nor fitted with a tilting cab, neither with high speed lifting and driving. Usually we hardly notice any difference in productivity gains if these higher lifting and driving speeds are available. Only at distances without interruption of 75 meters or more, pays a higher speed. Who often lifts over six meters, has an appreciable time gain from high speed lifting. In all other cases, it just takes energy and produces barely more productivity.

As we start working with the new Reflex, the adjustments to both the acceleration and braking pedals are striking. The result in a comfortable position of the heel on the floor during the ’throttle’. The position reduces pressure on the lower leg and improves pedal control.

Biggest gain of the new model and the improved electronics can be found in the much more predictable and speed sensitive steering. Toyota Material Handling offers the possibility to select your own (pre-set) type of power steering at the start-up of the truck. We experience the average selection as the optimum. The selection for the inexperienced driver is somewhat slow, while the one for the super-experienced driver is in our opinion too nervous. Either way, by offering this possibility the Reflex meets every taste. Nice detail: the automatic centring of the drive wheel is no longer done at start-up, but at turning off the truck. Thus, the start-up time is shorter and you still work safely with the certainty of the correct steering position.

The new electronics also includes improved performance of the mast functions, which are controlled more accurate, smoother and better at the same time thanks to the mini-levers. Reaction rates are as you would expect, which always works best. The control of the mast transitions can be summed up in one word: amazing. The mast slides completely shock-free, both in and out.

Altogether the new Reflex works better and easier than before. The view through the mast is more spacious and yet the right support leg remains unobstructed so you can position the truck easily and safely. The glass roof provides an incredibly spacious upwards view, but of course does require extra discipline to keep it that way. The optional laser assistance, for working at heights that are above the free lift of 2.3 meters, is very convenient. The laser pointer in the fork carriage projects both a horizontal and a vertical line, so as a driver you can clearly see whether you have the correct insertion height and width. To increase safety awareness, the system is only active when the fork is levelled horizontally. The optional auto-centring and auto-levelling make adjustment to the fork position very easy. We also experience more calmness in the mast thanks to the more rigid construction and a high degree of truck stability. Finally, the OTP (Optimal Truck Performance) system offers automatic and real-time adjustment of the driving speed and the mast and fork movements based on the current steering angle and lifting height. It makes the Reflex more predictable than ever before.

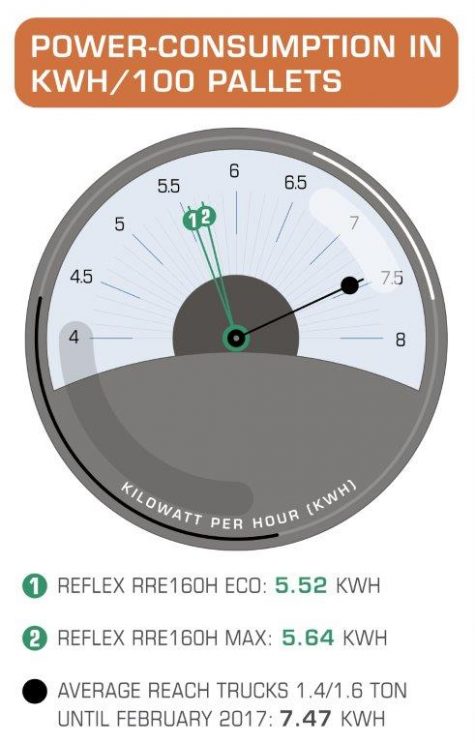

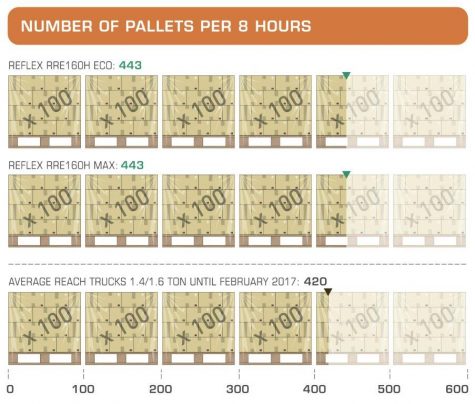

Regarding the performance of the RRE160H we mark only positive developments. Productivity has increased more than 10% compared to its predecessor in a similar setting, while energy consumption is 10% lower and significantly below the class average. Important gains are, as far as we are concerned, the improved steering- and mast-control, the higher lifting range, increased stability and improved visibility. Detail improvements such as the adjusted pedal arrangement and seating pay-off especially during intensive usage. In short, a truck does not always need to look brand new to still make a step forward. The new Reflex RRE160H is tangible proof for this.

Plusses:

For improvement:

(Test: Andersom Testing, Theo Egberts)

Tags:

Andersom test, Andersom testing, BT, BT Reflex, Reachtruck, Reachtrucks, TMHE, Toyota, Toyota Material Handling, Toyota Material Handling Europe

Back to basics With the introduction of the BB and ...

The Mexican logistics service provider Seglo Logistics,...

Stable powerhouse With the 6 to 8 tonnes ECB series...