With the EPL 154 and EPL 185 EP Equipment brings two almost identical powered pallet trucks with li-ion battery on the market. One with a 24V installation, the other with 48V for when it needs to be slightly more powerful. The trucks are easy to operate, score over average performance and are easy to charge via the built-in charger. Say goodbye to the hand pallet truck.

We wrote it before: Anyone today who still uses a hand pallet truck for regular transports is ergonomically not doing a good job. Up to a weight of approximately 250 kg, the manual ‘all-rounder’ is quite usable, but for heavier loads, usage of a manual pallet truck results in a lot of strain for the operator. Both lifting and pulling require too much force and can result in pain for the driver.

Since EP Equipment introduced the EPT 20-15ET in 2012, the industry has reacted and introduced many models in the segment of entry level pallet trucks. EP Equipment surprised the market in 2017 with the 12EZ and opened up the age of Lithium powered entry level trucks. In 2020 EP added a new line up of trucks for those who want a more powerful, robust and stable truck, the EPL 154 and EPL 185. Also equipped with a li-ion battery, and with significantly more ‘meat on the bones’. We put both newcomers to work.

With EP Equipment the user can choose between a 24V or a 48V setup. The 24V truck is the EPL 154 with a lifting capacity of 1.5 tons. The 48V EPL 185 lifts loads up to 1.8 tons. With the experience of more than 100.000 units annual production, EP Equipment uses LFP cells in combination with a sophisticated in house developed BMS system for all Lithium powered machines. According to EP’s statement: LFP cells have the advantage that they cannot burn, even when punctured or in case of an electric shortcut – safety in all situations. EP LFP batteries consist of stacks of flexible ‘pouches’. Another advantage of the pouch cells is a lower risk of damage, due to increased flexibility in the cell.

In terms of appearance and operation, the trucks are completely the same both for the EPL 154 and the EPL 185. Striking is the compact yet robust construction. Everything is made of steel and that creates a heavy-duty character. The hood around the drive wheel and both support wheels are low enough so the truck doesn’t run over the nose of your shoes when you’re too close.

The trucks are equipped with tandem fork wheels and the top of the fork is profiled. This is not only aesthetically pleasing, the recess between the front and rear profile is also the indication of where you can safely pick up a euro pallet across the fork without pushing the slats underneath when lifting. A wheel in the fork tips is missing, but we get the truck over the bottom battens effortlessly.

Compared to competing brands of electric pallet trucks in the compact segment, both EPLs are less heavy, weighing 157 and 170 kg respectively including the li-ion battery. Compared to the even more compact EP 12EZ they are heavier, but that extra mass has a positive effect during use. The EPL’s are more stable, smoother and really a bit stronger than their smaller brother. The 5-wheel configuration keeps them neatly on course, even with full load in a fast turn.

We are a little less enthusiastic about the accuracy of the controls while driving and lift/lower. The lift pump works via an on/off shift, there is little control in it. The question is whether you need it when it comes to getting a load off the ground and want to lower it again after moving it. When driving, a sensitive control is more important. Perhaps this can also be set via the hand terminal of the service engineer, we were not able to try this during the test.

Furthermore, the EPL trucks are easy to use. The drawbar is conventional in design with a butterfly switch for driving and push buttons for lifting and lowering. All commonly used functions can be performed with both left and right hand. At the push buttons for lift/lower we place a note. The operation of the button for lifting is done with the index finger. For lowering the button is just a bit too far away if you have smaller hands. With the middle finger you can reach it, but that feels a bit unnatural.

Those who often work in tight environments can easily operate the truck with an upright drawbar via a crawl position switch. This function is also possible to activate with both hands.

Furthermore, the operator clamping protection works correctly and smoothly. The emergency stop on the truck itself is easily accessible in panic situations.

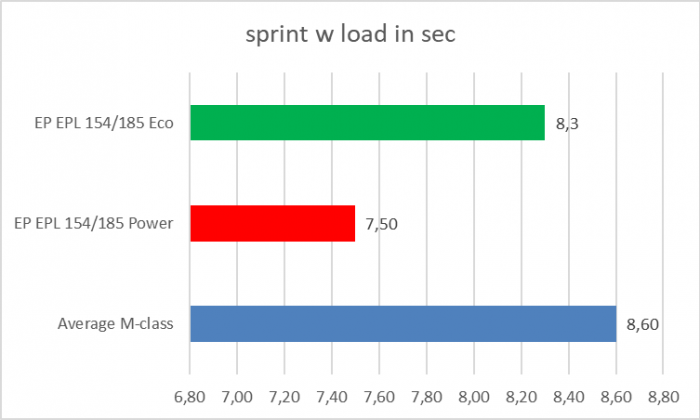

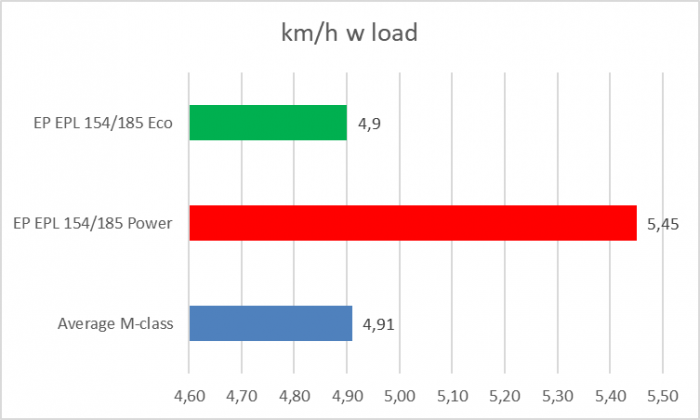

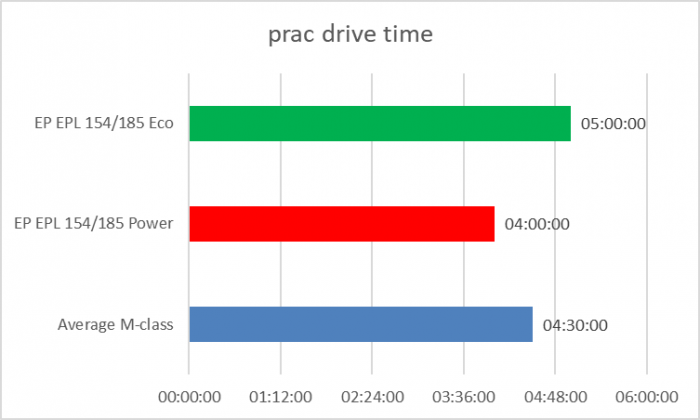

With the previously mentioned hand terminal of the service department, the performance of both EPL trucks can be adjusted. We have four different trucks at our disposal, and they are all set a little differently. So we see what the effects are of more or less acceleration and driving speed. Unfortunately we can’t measure the effect on battery life directly because our meter is difficult to connect to the trucks. We therefore estimate it via the battery discharge meter and arrive at about 4 hours of practical use in a powerful setting and 4.75 hours in an economical setting. The practical operating time is based on regular use with a mix of load weights ranging from 500 to 1,500 kg.

It also becomes clear that the more powerful setting makes the trucks more pleasant to use. Everything goes just a little smoother and that works fine. This applies to both truck types. The power difference between 48 and 24V is negligible if you set the power level of the 24V truck slightly higher than standard. The machine has no problem with the 1.5 ton on the forks. The EPL 185 even takes 1.8 tons and has a slightly more powerful motor on board with brushless DC technology. The pump motor of both trucks is equally strong.

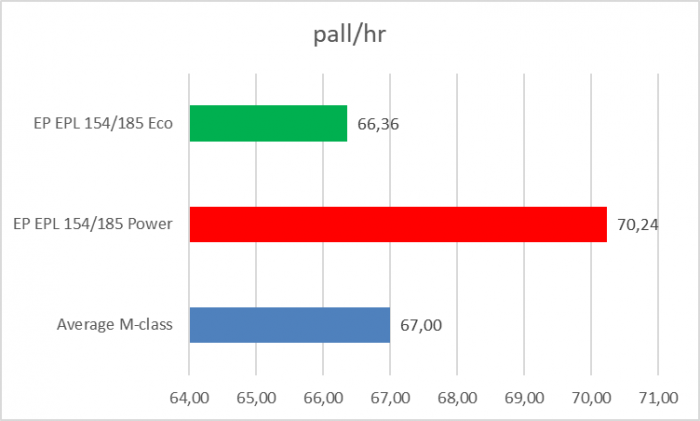

When it comes to performance, both EPL trucks from EP Equipment set a new benchmark at their price point in the segment of entry level pallet trucks. With over 70 pallets per hour in our test, they overachieved compared to our expectations for a pallet truck for under 2.500€

As a rule, a pallet truck such as the EPL 154 or 185 will not run continuous shifts. We therefore expect the trucks to be operational all day on a battery charge. Anyone who is in danger of running short of power can easily recharge via the built-in charger; just plug it into the 230V socket. If you have a second battery at your disposal, simply switch it. They weigh 8 kg (24V) and 12.5 kg (48V) and are easy to handle via their handle. To protect the connection pins of the battery, it is floating in the chassis. EP Equipment supplies optional external charging docks in which the battery can also be recharged outside the truck. Thanks to the li-ion technology, intermediate charging is no problem at all and you can top up the power source at any time. The batteries are completely closed, have a Battery Management System on board and are 100% maintenance free. Plug-and-play at its best.

With the EPL 154 and EPL 185, EP Equipment brings two well-functioning and performing trucks on the market. They are easy to use and solid in construction. Heavy loads are no problem and the stability is also great. The li-ion battery is maintenance free and easy to recharge or change. When you choose 24V or 48V depends on the settings and application. In fact, the 24V truck performs just as well if you give it a little more power. The 48V truck has a bigger battery capacity on board and has a longer runtime. Points for improvement, in our opinion, are the position of the fork lowering button and the accuracy of the drive control. This may be a little more sensitive. All in all, these new electric pallet trucks are yet another confirmation that frequent use of a hand pallet truck is no longer necessary.

(Text and pictures: Andersom Testing, Theo Egberts)

Tags:

Andersom testing, EP, EP Equipment, EPL 154, EPL 185, Intralogistics, Test

It has already been the case for three years that not j...

At LogiMAT 2022 in Stuttgart Jungheinrich presented th...

Wesco, a French SME established in 1975, creates, manu...