With the development of the loweringPRO mast, Jungheinrich crowns its already successful ETV216i reach truck. The new mast concept not only breaks Jungheinrichs market productivity records, but, above all, provides unprecedented smooth behaviour and better visibility. It is also much quieter than its predecessor.

With the introduction of the ETV216i with integrated li-ion battery, Jungheinrich set the tone in the reach truck market in 2018. Placing the battery under the seat gave the driver more practical cab space and better all-round visibility. The performance of the ETV216i remains the benchmark to this day, but there was barely any progress on one aspect: the mast. In previous tests we experienced some points of improvement: there is little or no damping at ground level and at maximum lift. The visibility could be better and the whole thing makes a clattering noise when driving. And with the arrival of a competitor with a rapidly descending mast, the importance of another market trend also became clear: reach truck warehouses are getting higher. Ergo, the usefulness of a fast-lowering mast with a low to medium weight on the fork is gaining ground.

With the LoweringPRO mast, Jungheinrich claims to have done away with all these objections. We therefore tested the ETV216i again and have a truck with a 6,500 mm mast for our test course (lifting up to 5,000 mm). We also tried out the 12,020 mm mast in a static setup.

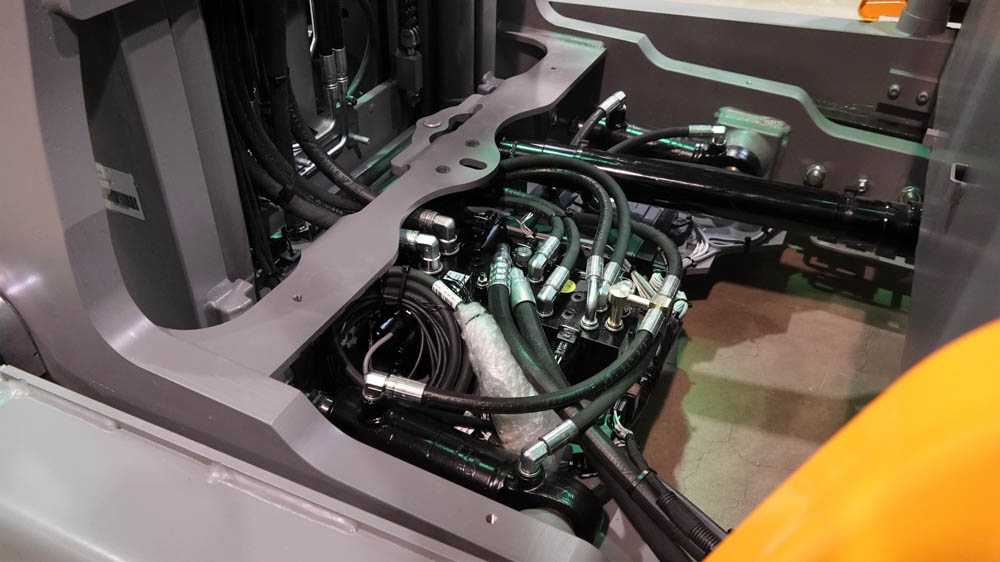

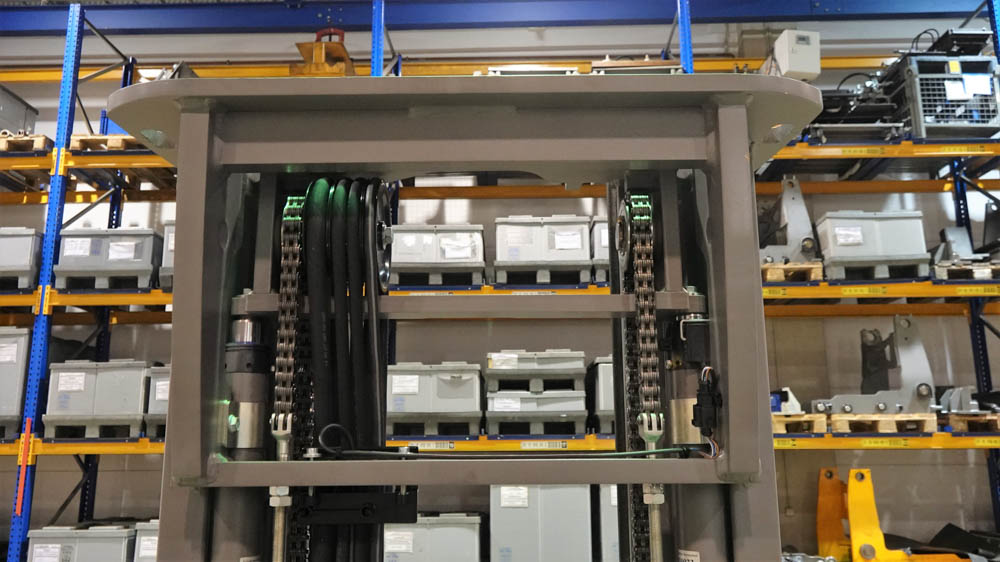

The question is of course: what does it deliver, but also what did the engineers do to arrive at the new mast concept? Under the motto ‘keep what is good and improve what can be improved’, the mast profiles themselves have remained the same. However, the cold-drawn profiles now have a hardened surface. The connection and routing of hoses and chains has been improved. The fork carriage has also been tackled and the cross connections have been reconsidered and recalculated. A new mast crown has been fitted and TPU blocks have been mounted in the lower sections.

The big trick of loweringPRO is a completely new hydraulic block with two circuits. Where previously one circuit always controlled the free lift cylinder first, now the oil flow runs to all cylinders simultaneously. The mast sections now move independently of each other, which has several advantages. As if all this were not enough, the ETV216i also has a completely new electronic control system with a larger internal memory and expansion options for the future. The on-board power level has been increased to 24V to better connect to external computer systems.

The effect of the visibility optimisations is immediately noticeable in a better visibility through the mast and the fork carriage, especially at common working heights between 1.5 and 2 metres. Even at greater lifting heights, at least one fork point always remains clearly visible. During lifting and lowering, loweringPRO ensures an unprecedented smooth mast movement. Shocks at mast transitions (both inwards and outwards) have disappeared completely and the fork can descend faster. Especially without a load, the mast now reaches a maximum lowering speed of 1.2 metres per second, which is twice as fast as before. This speed is particularly noticeable in the medium lift range between 5 and 12 metres and for loads up to 1 tonne. As a rule, the heaviest loads are not placed at extra-large lifting heights of up to 14 metres.

loweringPRO ensures that in the last metre all mast sections are lowered to the maximum and only the central cylinder is active so that the clearance height also remains correct and safe. Finally, Jungheinrich has now added cushioning at ground level and at maximum lift, which is very comfortable. Even more comfort is provided by the noise damping system at the bottom of the mast: rattling during travel is virtually eliminated. Never has a Jungheinrich reach truck been so quiet!

When looking at the performance of the 12,020 mm mast in the static configuration, it is noticeable that the peak speed of 1.2 metres/second is not achieved over the entire route. In total, the average lowering speed is between 75 and 80 cm/second, which is considerably faster than the 51 cm when the system is switched off. Our test truck with 6,500 mm mast also achieved similar scores. The best performance is achieved by replacing the test weight of 1,000 kg with a weight of 500 kg.

Jungheinrich also uses 500 kg as an average for high stacked loads in warehouses up to 14 metres. That is why loweringPRO is optimized for these kinds of weights.

Comparing the performance of our test truck with the values from the test we did in 2018 with the ETV216i, the lowering speeds differ significantly: no-load lowering then was 49.3 cm/sec and now comes to 68 cm/sec. With load, the average lowering speed increases from 55 to 78 cm/sec.

In our practical test for reach trucks we move 2 loads of 1,000 and 1,500 kg. The 1,000 kg load is lifted several times up to 5 metres, the 1,500 kg load is only moved horizontally. In our test, the loweringPRO mast delivers a productivity improvement of 4.4% if we perform the test with the usual 1,000 kg for lifting and lowering. If we lower the load weight to 500 kg, productivity increases to +9.1% because the loweringPRO system works more optimized. In both cases, Jungheinrich significantly improves its market productivity record. Of course, we also looked at the differences in lifting speeds between no-load, 500 kg and 1000 kg and these are negligible on the ETV216i with loweringPRO. As a bonus, the energy consumption during the test is also 2% lower. Regardless of the test weight used.

Can you therefore conclude that the gain measured in the 2021 version of the ETV216i test is entirely in the faster lowering system? No, not completely, but to a large extent. Another benefit we notice in the better visibility, the much smoother operation of the mast, the quiet ride and the higher feeling of comfort and grip on everything you do with the ETV216i like reaching out and in. As always, it’s all in the sum of the parts. As far as we are concerned, the ETV216i’s far greater comfort is its most important selling point, because you notice it every time you move a pallet, no matter how high or low you work. With the loweringPRO mast, Jungheinrich gives the ETV216i the mast it deserves. It is truly the icing on the cake!

Tags:

Andersom test, Andersom testing, ETV216i, Intralogistics, Jungheinrich, Jungheinrich ETV216i, LoweringPRO, Reachtruck, Test

With the ECB50, BYD is bringing a powerful alternative ...

Jungheinrich has just market-launched its new...

Hyster Europe has revealed more details about its zero-...