With the stacker ERC 216zi, Jungheinrich brings the logical sequel to the introduction of the reach truck ETV 216i. Both trucks are designed around the integrated lithium-ion battery. For the stacker this results in a more compact construction, including better visibility, higher performance and higher functionality.

In 2019, Jungheinrich launched its new stacker ERC 216zi. This year the newcomer will participate in the IFOY 2020 and that will definitely increase the worldwide awareness of the truck. We tested it and can conclude that the ERC216zi follows in the footsteps of the ETV 216i reach truck that appeared on the market a year earlier. Both trucks have been completely redesigned because the dominant shape of the interchangeable traction battery no longer exists. The truck gets it energy from an integrated lithium-ion battery, which is generally a lot smaller. In addition to that, a li-ion battery can be given a more free shape to fit even better into the design. For example, the li-ion battery on the ETV 216i reach truck is L-shaped for an optimal fit inside the truck.

In the Jungheinrich ERC 216zi the li-ion battery (24V/260 Ah) is simply rectangular, but neatly concealed behind the plastic (ABS) plating of the truck. If necessary, the battery is easily accessible and can be removed/replaced by the service department.

Thanks to the integration of the battery, the ERC 216zi remains very compact and offers plenty of space for the stand-in operator. In addition, it is protected on both sides and partly on the rear. A foot sensor (optional) monitors whether the feet also remain neatly on the footplate. If this is not the case, the truck automatically reduces the travel speed to a walking pace. All in all, you feel an extra degree of safety due to the surrounding protection. The side supports live up to their name: you can lean comfortably against them while driving. In addition, they offer extra grip thanks to the good handles on the top. At the bottom of the inside of the side walls we find two storage bins. To the right of the tiller is also a storage compartment with a paper clamp.

With its step height of only 195 mm, our test truck offers easy access. The sprung step platform is equipped with a comfortable rubber mat. Meanwhile, there is also an adjustable damping available, but this is not available on our test truck.

The smartPILOT tiller is easily adjustable in 5 height positions and can be operated very logically. With the butterfly switches you choose direction and determine the travel speed. On both right and left side we find the rocker switches for lifting and lowering the fork and the support legs. So you can operate the truck with left and right hand easily. Thanks to the initial lifting of the support legs it is possible to carry two pallets at the same time. The main mast is designed for a maximum load of 1,600 kg. In combination with the support leg levy, the total load capacity comes to 2,000 kg.

The electric steering system of the ERC 216zi works predictably, but due to the decentralised positioning of the travel motor, fast turns to the left or right do not feel identical. If the drive motor is on the inside, the truck can slide slightly out of corners. Curve Control helps to keep the cornering speed safe.

The renewed mast on the ERC 216zi offers lift heights of up to six metres, the mast on our test truck reaches up to 5,250 mm. The newly designed mast has a very wide viewing window. Thanks to the low dashboard, the fork tips are also easily visible. Our truck’s slimline protective roof is equipped with the optional glass panoramic roof and smart openings for mounting various items. The test truck is equipped with a colour display on which we can read many things that belong to optional assistant systems operationCONTROL and positionCONTROL. Amongst others, the display shows the current lift height, the maximum safe lift height, the load weight and the adjustable load centre. It is also very easy to determine and select presets for the lifting height. Should the system recognize an unsafe situation, for example a specific combination of load weight and lifting height, the display shows a warning, a signal tone sounds and the tiller vibrates. Whether the truck then automatically reduces the lifting speed or even stops is fully adjustable according to customer requirements.

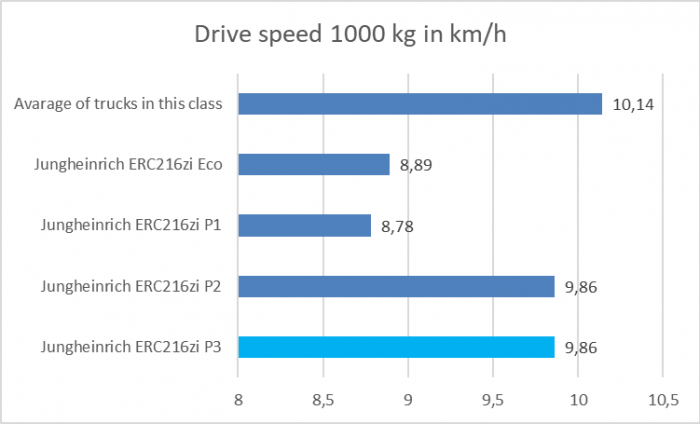

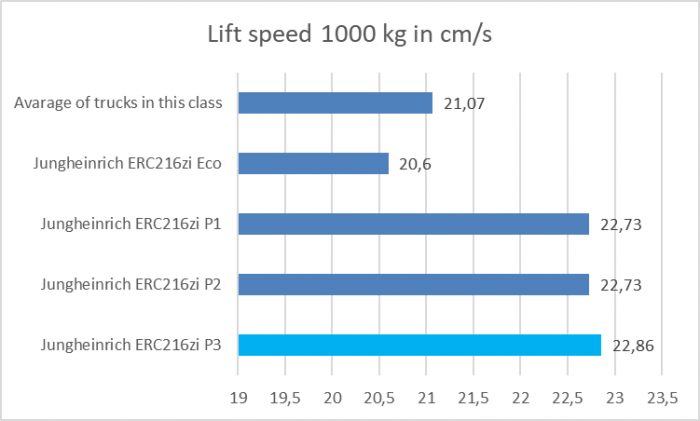

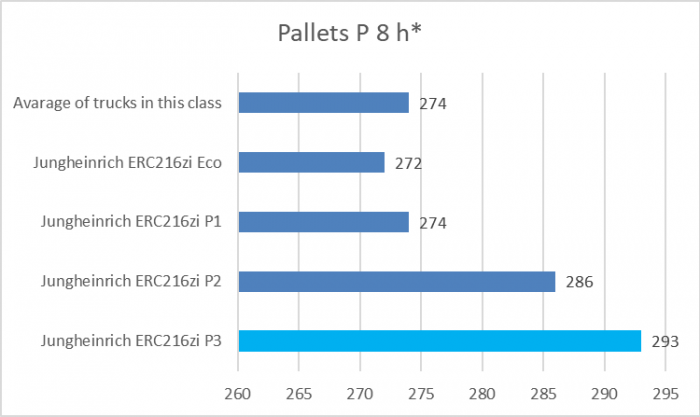

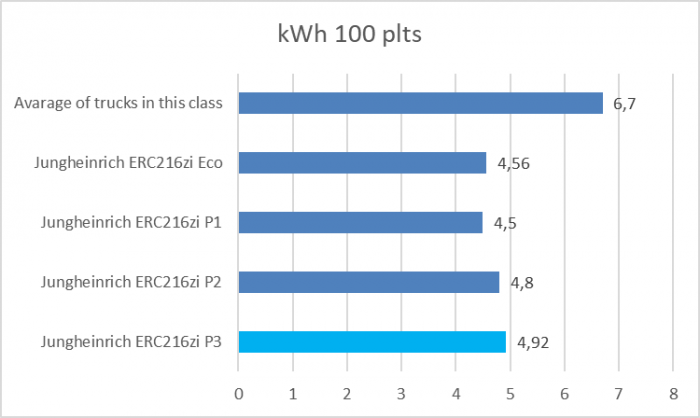

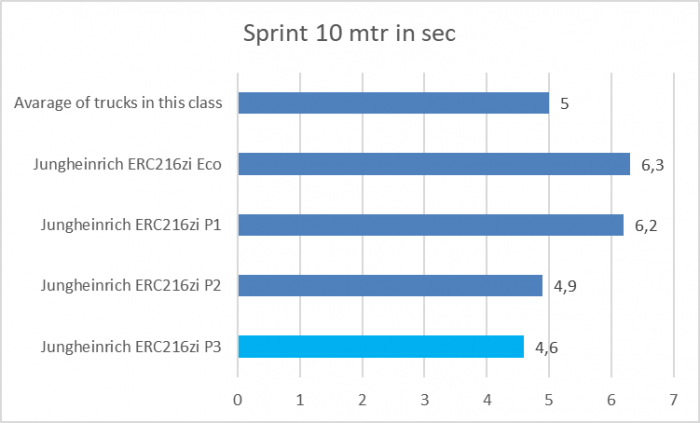

In terms of its performance, the Jungheinrich ERC 216zi scores convincing values. We drive the truck in all available driving modes. Acceleration is highest in P3 and P2, while in P1 and ECO there is much more emphasis on energy control and the transport of sensitive loads. Without a load we measure driving speeds of almost 12 km/hour, with a 1,000 kg load we reach almost 10 km/hour. Lifting speeds are above average and, thanks to easy handling and good predictability, we achieve above average productivity. Points for improvement, in our opinion, are the degree of mast damping when not lifting a load.

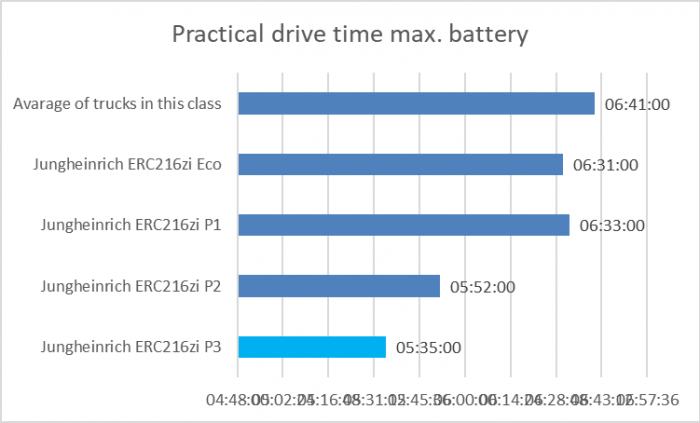

To optimize the building size of the truck and still have enough power on board for normal stacker duties, Jungheinrich limited the size of the lithium-ion battery to 260 Ah. Based on our measurements we arrive at a practical truck uptime of 5 hours and 45 minutes on the most powerful position P3. In ECO mode productivity remains at a good level, but we can work with a full li-ion battery for 6 hours and 30 minutes.

The stacker with standing operator is not the truck to it, but if you want to work with the truck with the lithium-ion battery continuously, it is easy to realize. You simply connect it to the charger during breaks, because lithium-ion batteries are carefree to charge in between. A quarter of an hour during the coffee break and half an hour during lunch and the truck can be used for almost 24 hours. What’s more, the batteries are maintenance-free, no gasses are released during charging and the number of charging cycles is more than 300% greater than that of a lead-acid battery.

Jungheinrich can supply the truck with either a 300A charger that can fully charge the battery in 1 hour or with a 25A built-in charger that is also available. The built-n charger can be connected to a normal 230V socket and has a charging time of 10 hours.

With the new ERC 216zi, Jungheinrich introduces an innovative, compact and very comfortable stacker truck to the market. The truck combines excellent performance with high ease of use and extra safety for the operator. The integrated lithium-ion battery enables carefree 24/7 use and is at the basis of a completely new truck design. Possible improvements include mast damping and a stronger automatic soft braking at lift limit.

(Text and photos: Andersom Testing, Theo Egberts and Mark Dohmen)

Tags:

Andersom test, ERC 216zi, Jungheinrich, Jungheinrich ERC 216zi, Test

Getting started in comfort With the new Riders series ...

Atomic Austria, the ski equipment manufacturer and glo...

Handy at the heights If you want to pick small items a...