With the EJC M10 stacker, Jungheinrich offers a serious alternative to its own industrial EJC 110. The M-stacker is a more favourable priced model and is particularly effective in light to medium intensive use. We list the facts and compare the newcomer with its brother and with the average in this market segment.

When it comes to internal transport over short distances and simple stacking, the pedestrian stacker offers all prospects of success. Compared to the forklift truck, the operation is considerably easier and the chance of collisions and serious damage is definitely a lot smaller. Add to that the much more compact construction, the lower purchasing price and the easy maintenance and the choice seems to be made quickly.

However, the supposedly limited lifting height and lifting capacity of stackers are often the reason why a compact forklift truck is preferred. Yet there is indeed development in the possibilities of the stacker and that is mainly at the bottom of the segment. Within the light class of 1 to 1.2 tonnes, budget models are added. Super convenient for example within stores and to carry out certain work at an ergonomically responsible height. This is why Jungheinrich recently enriched its range with the EJC M10. How does this truck fit together, what are the performances and where are the differences with its stronger counterpart the EJC 110? The test indicates it.

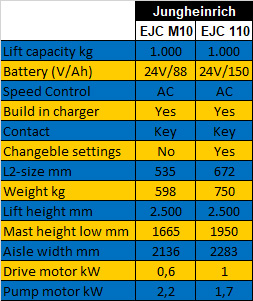

The Jungheinrich stackers in this test both have a lifting capacity of 1,000 kg and are equipped with a two-part mast with a lifting height of 2,500 mm. Both have a decentral (left placed) drawbar and built-in charger for a standard 230V socket. Yet you see at a glance that the EJC M10 is a different product. The truck is constructed much more compact , which results in a shorter L2 size and a lower hood under which the technology is concealed. The M10 is deliberately developed as an economical alternative for a very compact deployment under not too heavy conditions.

The technical data confirm this image. The M10 weighs 152 kg less than the EJC 110 and not the entire difference can be traced back to the other battery technology that the M10 carries on board. The chassis is slightly lighter, as well as the mast, the forks, the protective cover and the drawbar. The maintenance-free gel batteries are cleverly distributed over the space in the chassis so that everything can remain compact. With the EJC 110 the conventional lead acid battery is the dominant factor in terms of size and position in the truck.

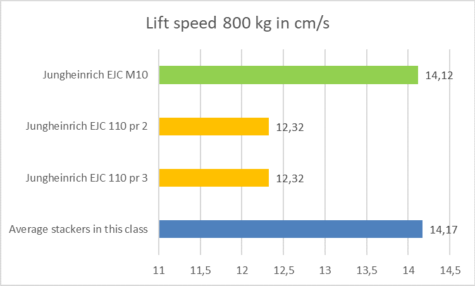

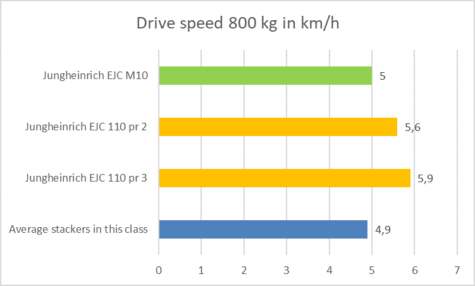

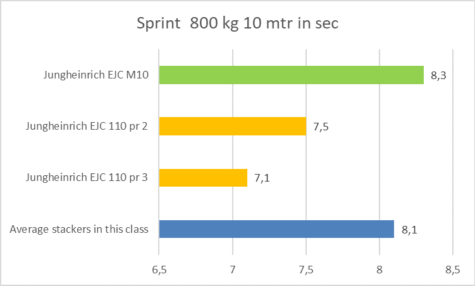

From the technical data you can also note that driving and lifting with the M10 is a bit slower compared to the EJC 110. During our measurements we can confirm this in part. The budget truck drives and accelerates measurably more slowly, but in fact accelerates faster. Perhaps that is the result of the stronger 2.2 kW lift pump motor, while the big brother has to do with ‘only’ 1.7 kW. Lowering with and without load is a big advantage for the EJC 110. The M10 drops 50% slower which completely eliminates the benefit of lifting faster.

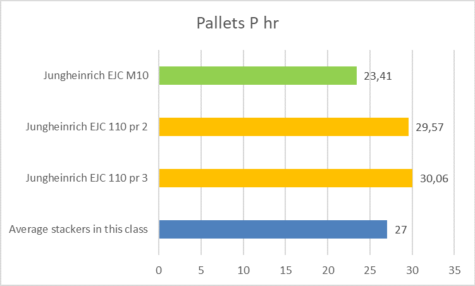

In our performance measurement the EJC 110 moves 28% more pallets per hour than the M10. This however is not shocking, because the stacker is usually not a ferocious production tool, but more a handy helper. Especially in this light segment, where size, purchase costs and ease of use are the decisive factor.

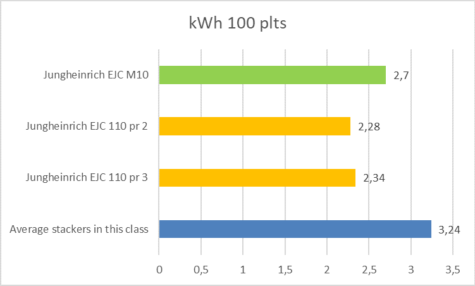

In energy values, both trucks score a similar consumption during the test. However, the M10 takes longer, so the energy consumption converted per pallet is with 10 to 15% (depending on the chosen driving program) to the advantage of the larger and stronger EJC 110.

If we compare the performance of both Jungheinrich trucks with the average of our test data in this 1-1.2 ton class, they both score lower energy consumption. In terms of productivity, the EJC 110 is above average, the M10 remains below.

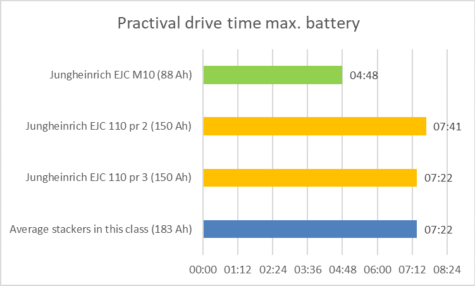

As mentioned, stackers are no ‘production animals’. It is the ease of use that counts and here the newcomer M10 has its advantages. In addition to the compact dimensions, the view of the fork tips is better and the battery needs less care. In both cases, charging can be done easy via standard sockets. Charging is more necessary with the M10, because the battery capacity is simply a lot smaller than that of the EJC 110. With a practical deployment time of around 4 hours and 50 minutes, the M10 will not pose its operator a problem quickly. Charging can take place at any time and without worries.

The EJC 110 is smoother in all its movements and makes audibly less driving noise. It feels more powerful, moves more pallets, offers more storage space on the hood and has 3 different driving programs ranging from extra powerful to very careful. Industrial construction makes this stacker more suitable for rougher deployment conditions. While handling heavier loads, the traction also seems to be better compared to the M10, which occasionally has a dragging drive wheel.Whatever the wishes of the user, as with the EJE M15 and EJE 116 pallet trucks from a previous test, Jungheinrich offers the user a serious choice: budget and simplicity or industrial and a little more power. It makes the spectrum of the stacker, which is in fact a super-handy and versatile mini-forklift truck, even more interesting.

Plusses:

For improvement:

Text and pictures: Andersom Testing, Theo Egberts en Mark Dohmen

Tags:

Andersom test, Andersom testing, Jungheinrich, Jungheinrich EJC M10ZT, Jungheinrich M-stacker, Stacker, Test, Warehouse truck

At the beginning of this year, Still introduced the bra...

Recently Jungheinrich exclusively showed Logistics Insi...

Arvato Supply Chain Solutions continues to advance the...