In addition to the efficient ETV 214i/216i series, Jungheinrich is now launching the ETV 3i series. The flagship is designed for demanding 24/7 operations. In our test, the newcomer lives up to all expectations. We see a highly predictable reach truck with high performance, an ergonomic workplace and a long deployment time.

In 2024, Jungheinrich introduced its new reach trucks from the ETV 2i series. Two models with 1.4 and 1.6 tonnes lifting capacity and specifically tailored to medium duty applications. More favourably priced than the most powerful models, because not everyone needs that, according to an extensive data analysis of Jungheinrich’s Fleet Management System. Complementing the launch of the ETV 2i series, the German manufacturer promised that the ETV 3i series was coming. These trucks are developed for intensive, say 24/7 deployment. At the recent LogiMAT in Stuttgart, the newcomer was shown publicly for the first time. We have since tested it.

Unlike the 2i series, the ETV 3i series includes not two, but five models rising from 1.4, 1.6, 1.8, 2.0 to 2.5 tonnes lifting capacity. The maximum lifting height has been increased from 10.7 metres to 14 metres and the residual lifting capacity is also higher. The same applies to all performance. From sprint to lift and travel speeds, everything is noticeably more powerful. This adds up to higher productivity. In the process, energy consumption remains very modest, but more on that later.

The ETV 3i series gets the extra power from the more powerful travel and lift pump motors and the larger drive wheel. Software-wise, there are also differences, reflected in a different setting of the parameters. In addition, the ETV 3i series has simultaneous control of the mast’s hydraulic functions as standard.

While in the ETV 2i series the gain was in lowering the cabin floor, in the ETV 3i series it is actually higher to accommodate the larger drive wheel and more powerful engines and pump. Our test truck has no separate step and has a floor height of 510 mm. This is not low, but also not insurmountable. Especially when you consider that reach trucks in intensive operation are often used for longer periods in a row. The driver then gets on and off less frequently.

For those who still like a bit more convenience when getting on/off, Jungheinrich also offers the ETV 3i-series with an extra step. During the test, we had an ETV 318i to experience this option in practice. The step is only 325 mm high and makes the cab accessibility easier. However, we did notice that the step takes away some foot space on the footplate. It’s not much, but on the truck without the step, you have just a little more freedom of movement. This also appears to be a wish of drivers who use the truck intensively, according to various driver responses during field tests and experiences with the previous ETV 214i/216i models.

As with the current ETV 214i/216i, the ETV 3i series also integrates the lithium-ion battery, keeping the truck compact and offering excellent all-round visibility. Given the more intensive tasks, the 3i series can carry not two, but up to three 230 Ah modules on board. With this 690 Ah, and thanks to its remarkably economical character, the ETV 314i has a practical deployment time of over 15 hours on its most powerful driving program P3 in our test. For a 24-hour deployment, the battery can easily be recharged during breaks. Another option is to choose a slightly more modest setting. On P2, we achieve a thick 17 hours and on P1 even 23 practical working hours.

Of course, productivity varies within the various programmes. On P3, we almost match the old record set by Jungheinrich with its earlier ETV top model. At the time, this truck was equipped with the loweringPRO rapid descent system and that just made all the difference. On P3, the newcomer is 15% more productive than the average of all reach trucks we tested. On P2 it is +11.4%, on P1 the ETV 314i scores equal to the market average.

We can be brief about the cab and other improvements of the ETV 3i series: they are similar to the previously introduced ETV 2i series. The new Jungheinrich display is colourful and provides clear data such as lift height and weight indication. The system has a digital load diagram that warns of possible overloading of the fork.

The steering wheel is unchanged, as is the 180/360-degree steering system (standard) and the highly predictable steering behaviour that has characterised Jungheinrich reach trucks for many years.

The console is adjustable in depth as standard, but unfortunately not in height. That is an option. While with the previous ETV 216i you could still choose three different, but fixed positions, with the ETV 3i models there is only one. This one sits just too high for our taste, making you work with a slightly raised arm. The second test truck does have the optional height adjustment, and it is fine: easily adjustable and very rigid in construction. In our opinion, height adjustment should be standard on trucks intended for intensive use.

In the cabin, we see improved storage options and a larger panoramic roof viewing window. On the roof edge, we find the unique SmartStripe LED unit. This daytime running light makes the trucks more noticeable during driving (white), cornering (flashing orange) and braking (red). Indication of the battery’s state of charge will soon follow. The colour of the light will then show how far the battery is charged.

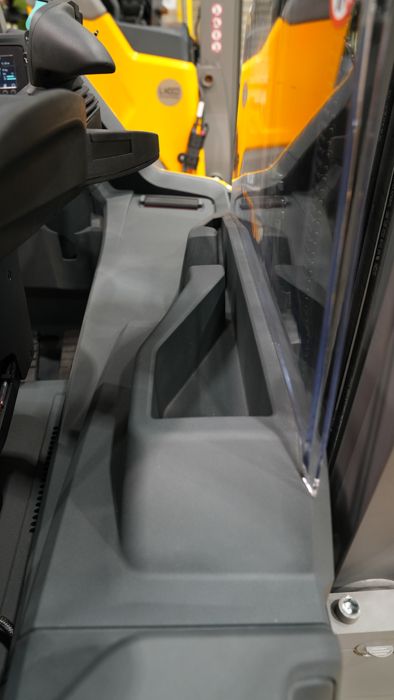

A novelty for the reach trucks comes in the form of a newly designed Plexiglas window between mast and cabin. This is higher and runs further around, reducing the amount of driving wind. We are not entirely happy with this variant, because when you want to get something from the storage compartments next to the armrest, your arm bumps against the, now still sharp, edge of the window. Jungheinrich promises to correct this shortcoming.

The new ETV 2i/3i series are more robust than their predecessors. The drive wheel cover makes maintenance for service easier and gives the truck a neater appearance. Any paint damage is much easier to repair. All trucks have improved and reinforced shoulder protection. Like the ETV 2i models, the ETV 3i series trucks are also available with the yellow wheel covers on the load wheels. These provide extra protection and more contrast, making collisions easier to avoid. The caps can be easily removed for maintenance.

Also extra safe and noteworthy is the optional patented Exit signalling system. Should the driver leave the truck before it comes to a complete stop, a clear alarm signal sounds.

With its higher performance, the new 3i series is the new flagship within Jungheinrich’s reach truck range. The truck is designed for intensive use and offers all the options for this when it comes to productivity, uptime and comfort. An additional mounting/dismounting step is available upon request, which will mainly be a personal choice. As scarce drawbacks, we mention the well-meaning but not yet fully developed wind protection and the lack of a standard height adjustment of the steering column.

(Text and photos Buro Andersom: Mark Dohmen and Theo Egberts)

Tags:

Andersom test, Andersom testing, ETV 314i, Intralogistics, Jungheinrich, Jungheinrich ETV 314i, Reachtruck, Test

To help support Just In Time manufacturing applications...

Stable powerhouse With the 6 to 8 tonnes ECB series...

As an expert for light, ergonomic powered pallet trucks...