At LogiMAT 2019, Jungheinrich will be presenting a new generation of its successful EKS medium/high level order pickers. As a result of numerous new developments, the truck achieves optimum performance with high storage density in a small space, while being the fastest truck with the largest order picking height for use in high-bay warehouses.

“We have trimmed the new EKS 412s for maximum performance – and in all matters that are important for use in the warehouse: performance, efficiency, ergonomics and safety,” explains Jungheinrich Board Member for Marketing and Sales Christian Erlach. “This enables us to offer our customers significantly higher throughput in their narrow aisle warehouse.”

New high-performance mast

New high-performance mastThe EKS is equipped with a novel staging-free triplex telescopic mast, which is unique in its class. At more than 14 meters, the EKS offers the largest order picking height among all vertical order pickers on the market. With a lifting speed of 0.5 meters per second, the EKS 412s is 25 percent faster than its predecessor, which is currently the fastest vertical order picker on the market.

The new EKS 412s combines performance and energy efficiency. By using a fuel-efficient synchronous reluctance motor, Jungheinrich has halved the energy losses on the motor side and increased the efficiency of the motor. In addition, the weight of the EKS has been significantly reduced during its redesign. Combined, this results in energy savings of more than 10 percent. Jungheinrich offers the EKS 412s with two battery options: proven lead-acid batteries and modern lithium-ion technology. Jungheinrich guarantees that the lead-acid battery powered EKS can cover two shifts with just one battery charge. This saves time and reduces operating costs. The use of lithium-ion technology guarantees high performance and maintenance freedom, fast charging time and a particularly long service life. Jungheinrich gives its customers a 100 % satisfaction guarantee for its lithium-ion technology with a full conversion right.

The new EKS 412s combines performance and energy efficiency. By using a fuel-efficient synchronous reluctance motor, Jungheinrich has halved the energy losses on the motor side and increased the efficiency of the motor. In addition, the weight of the EKS has been significantly reduced during its redesign. Combined, this results in energy savings of more than 10 percent. Jungheinrich offers the EKS 412s with two battery options: proven lead-acid batteries and modern lithium-ion technology. Jungheinrich guarantees that the lead-acid battery powered EKS can cover two shifts with just one battery charge. This saves time and reduces operating costs. The use of lithium-ion technology guarantees high performance and maintenance freedom, fast charging time and a particularly long service life. Jungheinrich gives its customers a 100 % satisfaction guarantee for its lithium-ion technology with a full conversion right.

Great importance was attached to the needs of the driver over the development of the EKS. The transition-free strokes of the new telescopic mast avoid shock impacts and enable comfortable and at the same time high-performance operation. Thanks to the optimised operating concept with all functions within reach, handling the EKS 412s is particularly easy.

Great importance was attached to the needs of the driver over the development of the EKS. The transition-free strokes of the new telescopic mast avoid shock impacts and enable comfortable and at the same time high-performance operation. Thanks to the optimised operating concept with all functions within reach, handling the EKS 412s is particularly easy.

All relevant information can be captured at a glance by the operator’s large colour display. With its barely noticeable actuation force, the new presence button is particularly user-friendly. Additional windows in the cabin rear wall ensure significantly improved all-round visibility.

Growing dynamics in the warehouse are creating ever more potential dangers. Therefore, another focus in the development process of the new EKS 412s was the issue of safety. Intelligent assistance systems ensure maximum safety combined with high travel dynamics and performance. These include a mobile personal protection and collision protection system, which thanks to obstacle detection by laser scanners ensures that the EKS complies with the necessary safety clearances. This enables the use of multiple trucks in a narrow aisle.

Growing dynamics in the warehouse are creating ever more potential dangers. Therefore, another focus in the development process of the new EKS 412s was the issue of safety. Intelligent assistance systems ensure maximum safety combined with high travel dynamics and performance. These include a mobile personal protection and collision protection system, which thanks to obstacle detection by laser scanners ensures that the EKS complies with the necessary safety clearances. This enables the use of multiple trucks in a narrow aisle.

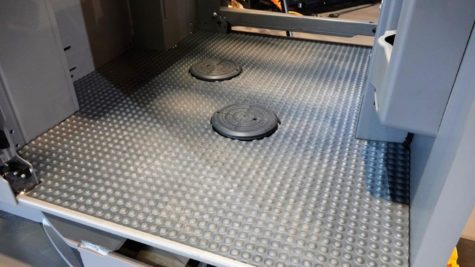

The Jungheinrich warehouseNAVIGATION system allows for an additional increase in performance and efficiency. Using the Jungheinrich Logistics Interface software, the truck can be easily and safely integrated into the IT system landscape available to the customer. Using RFID transponders in the ground, the truck detects its current position within the aisle. The operator simply has to give the travel/lift command and the truck approaches the pallet location automatically in diagonal travel mode.

Tags:

EKS 412s, Intralogistics, Junghein rich, Jungheinrich EKS 412s, LogiMAT, LogiMAT 2019, Order pick truck, Order picker, Order picking truck

Clark has launched a new high-lift pallet truck onto t...

At the IFOY Award Night 2023, in Dortmund, six compani...

With Serema, Clark Europe has found a new sales partner...