EP Equipment developed the JX1 a few years ago for picking small orders and performing other work at heights. Recently the JX0 has been added, functionally comparable, but lighter, slimmer and more compact than its big brother. However, the performance is impressive, as our test shows.

Anyone who occasionally picks small orders at a height or is looking for a task support vehicle to carry out (maintenance) work at heights, could use a mobile staircase or ladder for this purpose. Much quicker, and above all, more safe is the use of a compact man-up truck. Brands such as Crown supply the Wave, Jungheinrich has the EKM and EP Equipment offered the JX1 so far. This truck is clearly heavier in construction than the other two models and could be called, more or less, an industrial order picker. We tested this truck in 2018 and saw that it performs very well thanks to its high working height, fast cycle times and easy handling.

Anyone who occasionally picks small orders at a height or is looking for a task support vehicle to carry out (maintenance) work at heights, could use a mobile staircase or ladder for this purpose. Much quicker, and above all, more safe is the use of a compact man-up truck. Brands such as Crown supply the Wave, Jungheinrich has the EKM and EP Equipment offered the JX1 so far. This truck is clearly heavier in construction than the other two models and could be called, more or less, an industrial order picker. We tested this truck in 2018 and saw that it performs very well thanks to its high working height, fast cycle times and easy handling.

To respond better to the demand for compact and lighter built vehicles, EP Equipment is now launching the JX0. The truck is more like its German and American competitor and is clearly a relative of the JX1 given its colour scheme, no-nonsense approach and its completely different approach in terms of driving and steering system, We are therefore very curious how he will pass our test.

The EP Equipment JX0 is one of those trucks where you immediately understand how it works. You step through the safety gates on the platform of the cab and activate the truck with the ignition key. On the right, you’ll find a handle with a thumb switch that determines speed of travel. With a set of buttons above you control the lifting and lowering of the stand-on platform and the adjustment of the tray in front of you. It’s all as simple as it is logical.

The EP Equipment JX0 is one of those trucks where you immediately understand how it works. You step through the safety gates on the platform of the cab and activate the truck with the ignition key. On the right, you’ll find a handle with a thumb switch that determines speed of travel. With a set of buttons above you control the lifting and lowering of the stand-on platform and the adjustment of the tray in front of you. It’s all as simple as it is logical.

On the left you will find the steering wheel, currently a unique function of the JX0. Thanks to optical sensors, the truck knows if you want to operate it. The truck is only active with both hands in the logical working position. If you let go of one of your hands, the vehicle comes to a safe halt. Further work is only possible with both hands in the right place. A switch under the footplate also keeps an eye on you so that it can be operated safely under all circumstances.

Steering the JX0 is particularly easy and predictable. Just like a reach truck, you can steer with the central, front-mounted drive wheel. Two support wheels at the corners ensure that the truck remains both agile and stable. EP Equipment explained that they choose a drive system that is based on the concept of steering rather than turning the vehicle, making it very predictable and smooth to drive.

Steering the JX0 is particularly easy and predictable. Just like a reach truck, you can steer with the central, front-mounted drive wheel. Two support wheels at the corners ensure that the truck remains both agile and stable. EP Equipment explained that they choose a drive system that is based on the concept of steering rather than turning the vehicle, making it very predictable and smooth to drive.

Compared to the EP Equipment JX1, the JX0 achieves a lower platform height and slightly less load-bearing capacity. Where the big brother gets up to 4,880 mm standing height, good for a picking level of 6,500 mm, there the JX0 brings the operator up to 3,000 mm and you get a pick height of 4,500 – 4,700 mm. Fully loaded, the JX1 carries 500 kg, while the JX0 can handle a total of 336 kg: 110 kg on the lower deck, 90 kg on the worktop and 136 kg for the operator.

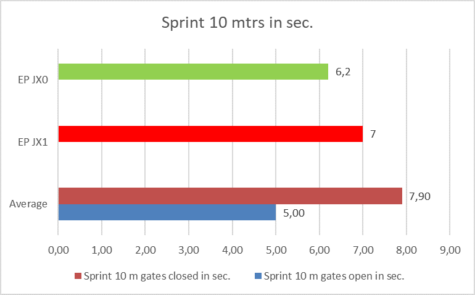

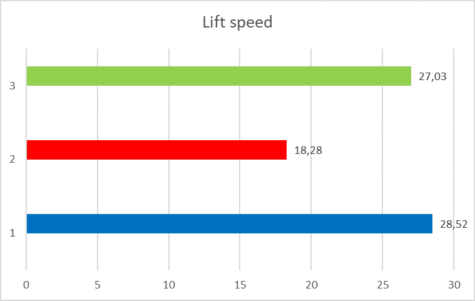

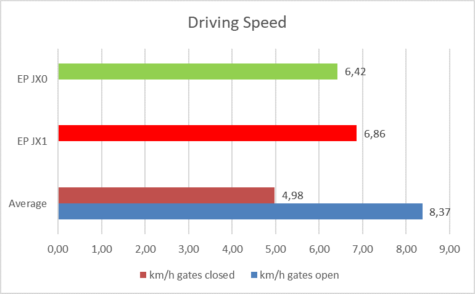

In terms of speed, the balance clearly points out in the direction of the JX0. Our measurements show that it sprints faster over 10 meters and has a noticeably smoother and faster lift than its big brother. The driving speed is almost the same. The faster response of the JX0 shows that it is much lighter in weight, yet also offers its operator a stable and secure workplace.

In terms of speed, the balance clearly points out in the direction of the JX0. Our measurements show that it sprints faster over 10 meters and has a noticeably smoother and faster lift than its big brother. The driving speed is almost the same. The faster response of the JX0 shows that it is much lighter in weight, yet also offers its operator a stable and secure workplace.

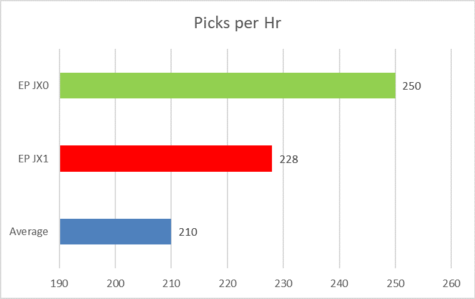

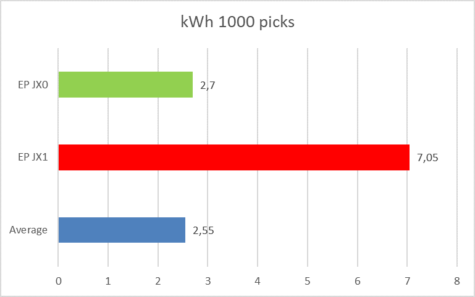

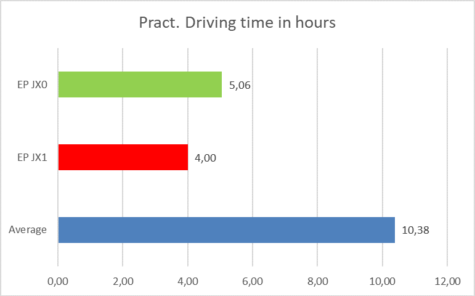

The ease of getting on and off the JX0 strongly depends on the physique of the operator. If you’re ‘not that slim’ then you’re looking for a flexible way to ‘flow’ through the fences, but that’s something we’ll soon be able to get hold of. The working space on the truck is more than sufficient when the gates are closed. After a first run in the test with 8 picks at our standard test track with different picking heights, we found the settings of the truck to be too aggressive. The automatic deceleration of the driving speed when working at height was too strong. In addition, the speed reduction in bends was set too strongly and the switch-on and switch-off moments were at extremely safe steering angles. Based on our experience, the EP Equipment technician adjusts the settings to our needs. The result: a smooth driving and steering truck that does exactly what you expect. The safety is still optimal, because with extreme steering angles and/or combinations of driving speed and lifting height, everything remains neatly manageable. Productivity is thus 20% higher and reaches the highest level we have ever achieved with these types of trucks: 250 picks per hour. The energy consumption is in line with the market. With these settings, we arrive at a practical deployment time of more than 5 hours.

Multiple safety

Multiple safetyCharging of the maintenance-free AGM batteries (2x 12V) is easy via the built-in charger with 230V plug. As soon as you remove it from the truck, all movements of the JX0 are locked. The safety of the lifting mechanism of the platform is also well regulated. Four switches monitor the position of the chains and cylinders, if there is a problem then descending is only possible in creep speed. For service and other purposes, the JX0 platform lift can also be operated from the side of the truck. Even in the service mode, switches ensure the safety of the mechanic and the platform can never be lowered accidentally.

As standard, the EP Equipment JX0 is equipped with electric-hydraulic levelling of the work tray, a battery discharge display with position indication of the drive wheel, a Blue Point on the front and an orange flash on the rear. The column below the control unit has various fixing points on both sides to which scanners and other equipment can easily be attached.

The JX0 is not richly equipped when it comes to storage space. We only find a paper compartment and two round ‘cup holders’ on the front side of the side panels. A pen holder or an extra storage tray can easily be attached on the column and may be part of the standard equipment as far as we are concerned. We would also suggest to mount a protective strip on the relatively sharp edges of the side panels to give the truck a better finishing and reduce the risk of injuries. EP promised a change in production on this matter.

The JX0 is not richly equipped when it comes to storage space. We only find a paper compartment and two round ‘cup holders’ on the front side of the side panels. A pen holder or an extra storage tray can easily be attached on the column and may be part of the standard equipment as far as we are concerned. We would also suggest to mount a protective strip on the relatively sharp edges of the side panels to give the truck a better finishing and reduce the risk of injuries. EP promised a change in production on this matter.

Conclusion

ConclusionWith its compact design and easy operation in the JX0, it is an asset to what some call a Work Assist Vehicle and others a Task Support Vehicle. The truck makes it possible to easily reach pick-/work heights of 4,500 mm. Performance is currently the benchmark in the industry and is the sum of easy and predictable steering, smooth acceleration and good diagonal movement between locations with different working heights.

(Text and pictures: Andersom Testing, Theo Egberts and Mark Dohmen)

Tags:

Andersom test, Andersom testing, EP, EP Equipment, EP JX0, Intralogistics, JX0, Order pick truck, Orderpicking, Test, Truck test

No more compromises With the new ERE 225i and ERD 2...

It has already been the case for three years that not j...

Recently Jungheinrich exclusively showed Logistics Insi...